WEBOMATIC®

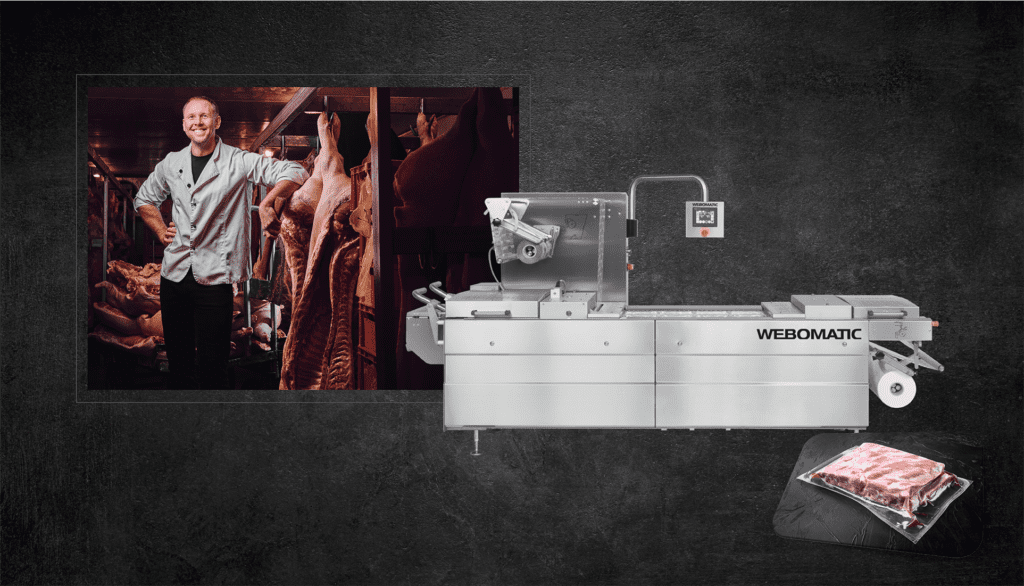

ML-C 5600-Skin

Skin-Thermoforming Machine

- Protrude-Skin packaging by full-surface

sealing without modifying the shape or

color of the product.

- High puncture-safety guarantees the best

possible protection against external influences.

- Reduced use of materials for less

resource consumption.

- Max. draw depth of 70 mm for flat and

exclusively looking packagings.

WEBOMATIC® ML-C 5600-Skin

Skin-Thermoforming Machines

- Protrude-Skin packaging by full-surface sealing without modifying the shape or color of the product.

- High puncture-safety guarantees the best possible protection against external influences.

- Reduced use of materials for less resource consumption.

- Max. draw depth of 70 mm for flat and exclusively looking packagings.

WEBOMATIC

ML-C 5600 Skin

Skin - Thermoforming Machines

With a thermoformed skin pack, your product receives a skin-tight enclosure of a clear-transparent top film.

This special skin film is being sealed full-surface onto the bottom film without impairing the product.

The result is packaging of outstanding quality with increased food safety and the best possible product presentation, regardless of whether the product is presented hanging or lying at the point of sale.

WEBOMATIC® ML-C 5600 Skin

Skin - Thermoforming Machines

With a thermoformed skin pack, your product receives a skin-tight enclosure of a clear-transparent top film. This special skin film is being sealed full-surface onto the bottom film without impairing the product.

The result is packaging of outstanding quality with increased food safety and the best possible product presentation, regardless of whether the product is presented hanging or lying at the point of sale.

Thermoformig Machines ML-C 5600-Skin

More Advantages at a Glance:

-High product protection and easy opening of the packaging.

-Leak-proof packaging - more hygienic, healthier and appealing.

-Stand-out product presentation thanks to skin packaging with high recognition effect at the point of sale.

-Resource-saving thanks to lower material usage

-Reduced volume of packaged product can reduce costs

Thermoformig Machines ML-C 5600-Skin

-High product protection and easy opening of the packaging.

-Leak-proof packaging - more hygienic, healthier and appealing.

-Stand-out product presentation thanks to skin packaging with high recognition effect at the point of sale.

-Resource-saving thanks to lower material usage.

-Reduced volume of packaged product can reduce costs.

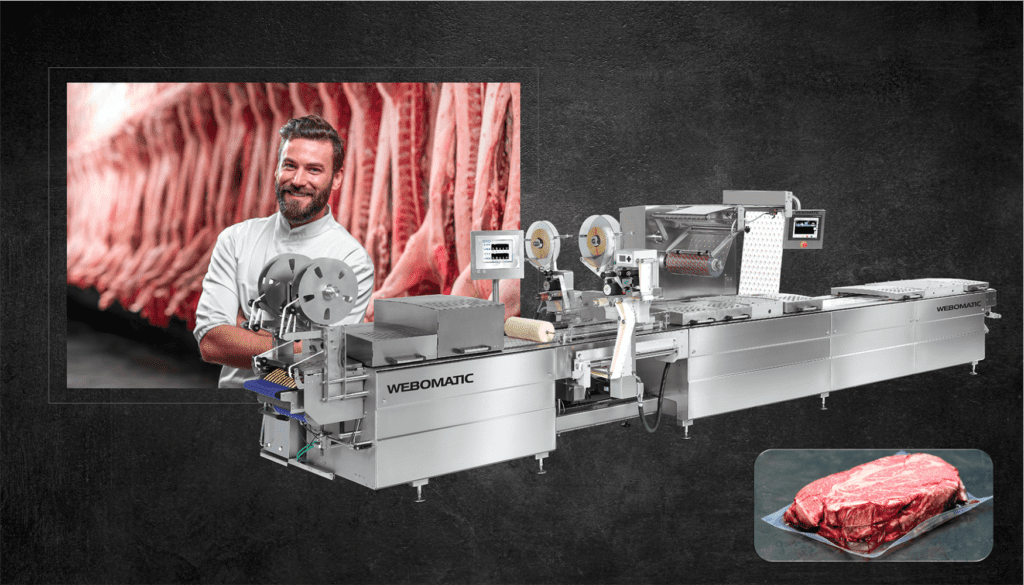

WEBOMATIC® thermoforming machines extend the shelf life of your food.

In this way, they reach the end consumer's table with their freshness, color and taste intact.

Packaging examples

Distinctive packaging designs

Examples of Packaging

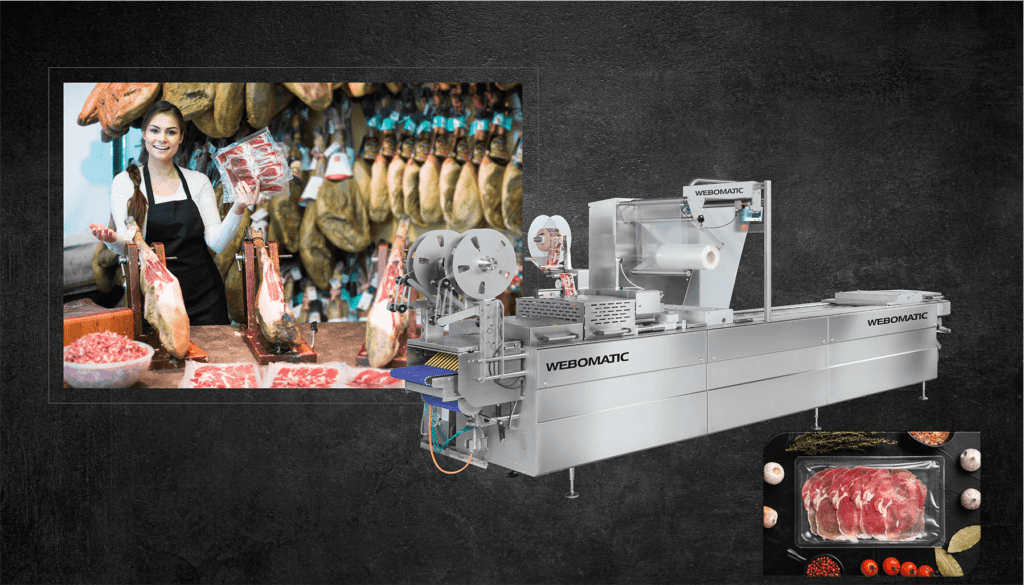

Whether meat, fish, poultry, cheese, dairy products, pâtés, or seafood - the thermoforming skin packaging process ensures optimal product presentation.

WEBOMATIC® Thermoforming Machines

Rigid foil die-cutter: Produce representative packaging with round corners, also for protruding products.

our multiple options

Customize your packaging

The WEBOMATIC® Thermoformers offer a wide range of optional special equipment - be it special forming processes, cutting techniques, labeling or synchronization with other machines.

ML-C 5600-Skin

WEBOMATIC ML-C 5600 Skin is an additional variation that has been further developed according to the properties of the ML-C 5600. With a thermoformed skin pack, your product receives a skin-tight enclosure of a clear-transparent top film. This special skin film is sealed full-surface onto the bottom film without impairing the product.

The result is a pack of excellent quality with enhanced food safety and the best possible product presentation – No matter if meat, fish, poultry, cheese, dairy products, pâté, or seafood the thermoforming skin packaging process ensures an ideal product presentation. – Even seafood, shrimp, or types of fish (e. g. hot-smoked salmon) are kept fixed in the pack and presented in an appetizing way.

Skin packaging allows for a free choice of product presentation at the point of sale, whether the package is displayed in a hanging or lying position. Meat juice, for example, cannot seep out of the red meat. The product remains visibly juicy and fresh for the end user

This high-tech machine is equipped with highly dynamic servos, processes film width of up to 560 mm, and creates all conceivable cutting options, including a combined a roll shear strip cutting and a cross strip punch to avoid “cat nails” with thick bottom films.

Depending on the packed product (for example, cheese or meat), specially developed skin films can be used to support maturing or breathing, whatever the respective food requires.

Of course, this thermoforming machine belongs to the WEBOMATIC CleanDesign generation.

| Technical Specifications | |

| ML-C 5600 | |

| Area of Use | Food, Non-Food |

| Machine dimensions: | Length: 5.260 – 19.500 mm Width: 1.030 – 1.270 mm (depending on film width) Height: 1.980 mm (± 35 mm) |

| Size / Capacity | ●●●● |

| Output | ●●●● |

| Degree of customization | ●●●● |

| Packaging shape variants | freely definable |

| Packaging style | Vacuum, MAP, Pseudo-skin, |

| Protrude-skin, Form shrink, 2pack | |

| Repeat length/Index: | 200 – 600 mm |

| (max. 400 mm with pre-heating) (only skin: 200 – 400 mm) | |

| Draw depth | Max.130 mm / max. 70 mm – skin |

| Bottom film width | 322 – 562 mm |

| Bottom film: Flexible film | PA/PE, Tyvec, max. 1200 μm |

| Bottom film: Rigid film | e.g. PET, PVC, PP, PS |

| Top film: Flexible film | e.g. PA/PE, Tyvec, PP |

| Top film: Rigid film | Optional |

| WEBOMATIC CleanDesign® | ● |

| WEBOMATIC Sealing Technology | ● |

| Forming procedures | Standard: compressed air |

| Optional: compressed air and vacuum, | |

| plug assist forming | |

| Top film forming | Optional |

| Cutting | Standard: guillotine cut |

| Optional: Zigzag cut, Perforation cut, Round corners, Squeezing knife, Strip punch, Contour or complete cut | |

| Film rewinding with dancer arms | Optional |

| Peel Corners | Optional |

| Pre-heating | Optional |

| WEBOMATIC On-The-Fly Format Change | Optional |

| Pseudo-skin | Optional |

| Protrude-skin | Optional |

| WEBOMATIC 2pack | Optional |

| Form shrink | Optional |

Options for Packaging Customization

| • Print mark control |

| • Pseudo-Skin |

| • Protrusion-Skin |

| • Form shrink |

| • Various cutting systems |

| • Opening aids, such as peel corners, bend peel, etc. |

| • Various pack coding and printing systems, such as: |

| – Labelling equipment |

| – Print mark control |

| – Stamp coding |

| – Thermal transfer printers |

| – Ink jet |

| – Laser systems |

Other options are available, CONTACT US!

We will gladly advise you

Options for Packaging Efficiency and Process Optimization

| • Support rollers in the loading zone |

| • Film strip rewinder |

| • Height-adjustable split conveyor belt |

| • Safe water cooling system |

| • Stroke limitation via PLC-control |

| • Synchronization with automatic supply system |

| • Preheating systems |

| • Various PLC control based tools: |

| – Remote diagnostics |

| – Advanced production data analysis |

| – Customization and tailoring of further |

| – Digitization concepts |

More options are available , Get in Touch!