WEBOMATIC® SHRINKING MACHINES

WEBOMATIC shrink packaging and drying units are designed to significantly improve the presentation of your final product.

These units deliver exceptional results with advanced temperature penetration and energy efficiency. Hot water shrinks the pre-sealed vacuum shrink packs around the product like a second skin. Compared to traditional vacuum packaging, shrink packaging offers wrinkle-free transparency, ensuring that your products are always packaged to perfection. In addition, they prevent the escape of product liquids and can further extend the shelf life of the products.

What’s more, their precise and accurate construction makes them easy to operate and control.

You can seamlessly integrate these units into your existing production line or new setup, providing a hassle-free solution to enhance productivity.

WEBOMATIC® Shrink packaging extends the shelf life of your products, significantly improving their presentation and ensuring that they reach the consumer with color, freshness, and flavor intact.

Would you like to know more?

Contact us

WEBOMATIC®

Standard Machines

Shrinking ST 40

The shrink tank ST 40 convinces by high efficiency and low energy consumption. Heated within minutes, the semi-automatic shrink tank easily processes medium packaging quantities

WEBOMATIC®

Space-saving Shrink Lines

Flexibility down to the last detail

We are proud to offer our semi-automatic shrink tanks ST 40, which can be combined with WEBOMATIC® vacuum packaging machines on request, to create a compact and affordable shrink packaging line that cannot be beaten.

These shrink packaging lines provide space-saving and cost-effective shrink packaging solutions for small to medium-sized packaging requirements.

Discover the following options that allow you to adapt the machine to the requirements of your products.

OPTIONS

Roller Platform

Steam exhaust hood

Single or Three Phase current

Special Voltage or Frecuency

Conveyor Table

Holding mechanism of the diving position

Lid

Stainless steel lid for prevention of steam discharge

Product Table

Stainless steel product display left or right

Automated Solutions for

Shrinking and Drying

STCW 60 & DU 60 - STCW 80 & DU 80

Fully automatic shrink tunnels from WEBOMATIC are the ideal solution for industrial-scale packaging finishing and are geared to efficiency, which also includes intelligent resource management (water and energy).

The industry-compatible WEBOMATIC automatic shrinking and drying systems are based on four state-of-the-art models in terms of materials, construction, equipment, and design.

All models are driven by a magnetic coupling and therefore operate very hygienically and wear-free.

WEBOMATIC®

DU 60 & 80

Our DU 60 and DU 80 dryers carefully and gently dry shrink packs, preparing them for the next steps, such as weighing, labelling and cartoning.

The dryers can be connected to the matching shrink tunnels STCW 60 and STCW 80 and run in the same seamless operation.

Photocell-controlled, the products are carefully dried with the perfect distance to the product surface.

OPTIONS

Heat Exchanger

Electrical- and Steam Heating

Increase of Capacity

Frequency Converter

Special voltage or frecuency

Cleaning /decalcification

STCW 60-T:

Individually assessable via touch screen

Photocell

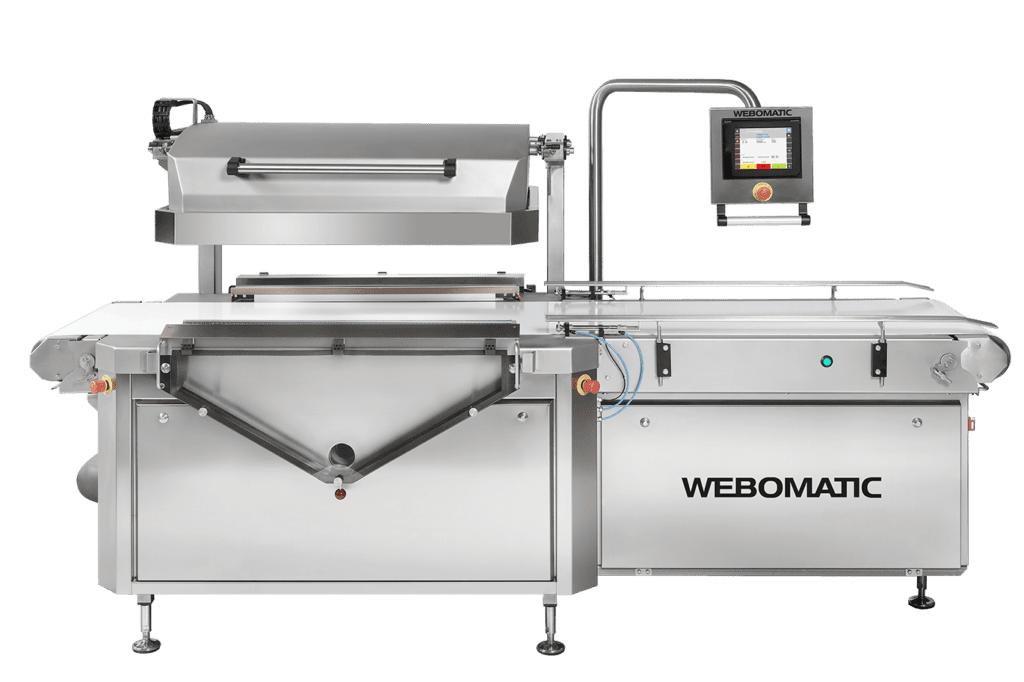

Line Competence for the Industrial Use

CL-C 950 & STCW 60 & DU 60

The high-performance WEBOMATIC chamber belt machines are the ideal basis for line applications. Flexibly expandable to complete packaging and shrink lines with shrink tunnels, dryers, variable conveyor belts, product depots or turntables WEBOMATIC.

The chamber belt machine and shrink components can be easily integrated into the production. The entire shrink line can be comfortably operated and monitored via a central touch screen on the chamber belt machine

…The result, all around perfect shrink packaging, durably sealed and gentle on the product.

PERIPHERALS

Click on the name of the Peripherals

to learn more

WEBOMATIC®

FKT 800

Klicken Sie auf den Namen der jeweiligen Anlage,

um mehr zu erfahren

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

WEBOMATIC®

LS 150