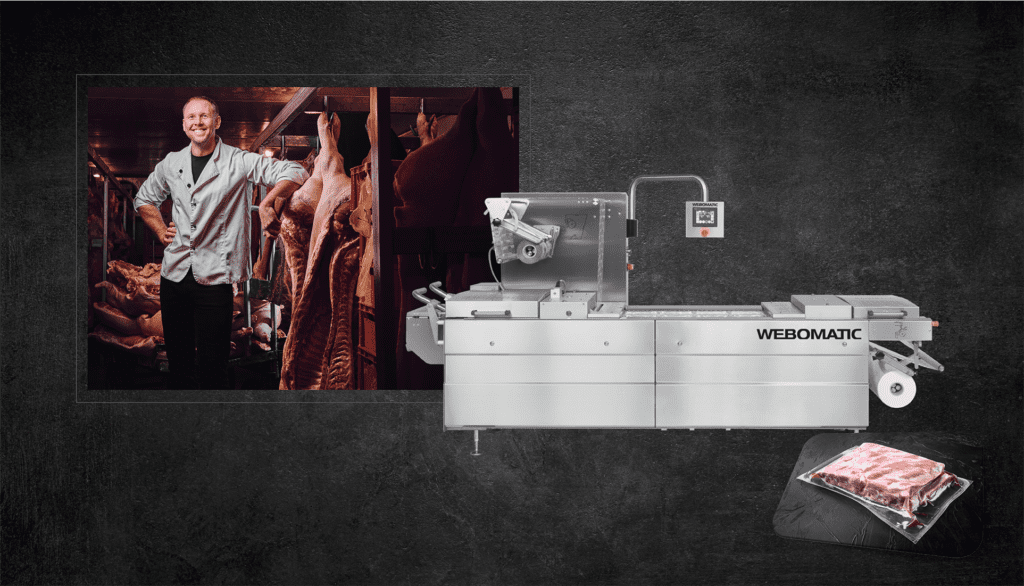

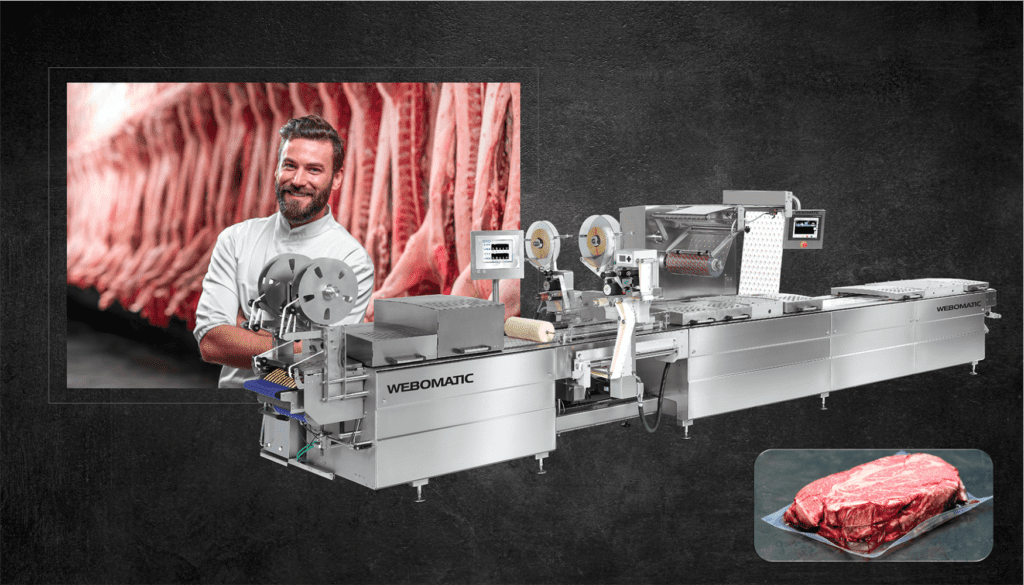

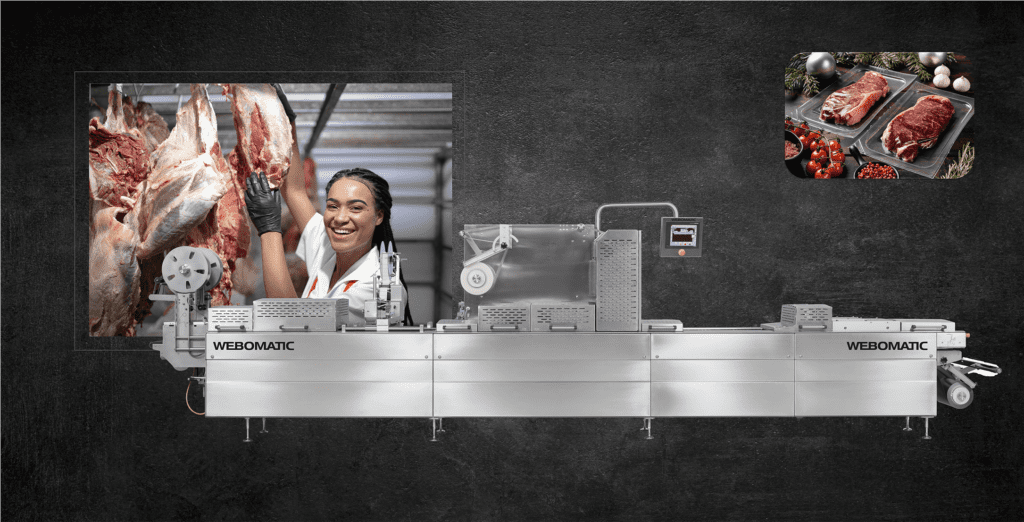

Compact, but with high-quality thermoforming technology nonetheless: the WEBOMATIC® ML-C 2600 is an entry-level thermoformer that fits into almost any application.

The machine will package your products quickly and cost-effectively with full-featured thermoforming technology. This thermoformer is ideal for small to medium production runs.

The machine is equipped with a swivel monitor that allows operation from either side of the machine. If preheating is required, there is no need to reduce the loading zone, and optional interchangeable forming inserts allow product changes to be made in minutes.

The list of options is quite impressive.

Depending on the specification, the ML-C 2600 can process rigid films up to 600 μm and up to 422 mm wide in multiple repeat lengths of up to 300 mm.

The cleaning mode allows a full wash down with covers removed.

Options for packaging customization

• MAP

• Oxygen O2

• Detection system

• Skin or form shrink wrapping

• Gas mixer and/or analyzer

• Preheating systems

• Various cutting systems

• Opening aids, such as peel corners, bend peel, etc.

• Various pack coding and printing systems, such as:

– Labelling equipment

– Print mark control

– Stamp coding

– Hot stamping

– Thermal transfer printers

– Ink jet

– Laser systems

Options for packaging efficiency and process optimization

• Support rollers in the loading zone

• Film strip rewinder

• Height-adjustable split conveyor belt

• Safe water cooling system

• Stroke limitation via SPS control

• Synchronization with automatic supply system

• Various PLC control based tools:

-Communication module

– Remote diagnostics

– Advanced production data analysis

– Customization and tailoring of further

– Digitization concepts