Looking for a reliable, high-performance solution for your industrial mass production needs?

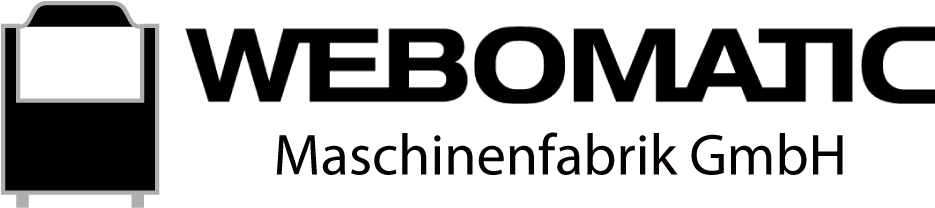

Look no further than the WEBOMATIC ML-C 7600! Capable of producing demanding vacuum formed packaging in up to three shifts per day, this state-of-the-art machine has been designed with decades of experience to provide unparalleled speed, precision and potential.

Depending on the equipment included, this industrial vacuum forming machine can expertly process all common film materials with a width of up to 662 mm, a draw length of up to 1,000 mm and a draw depth of 190 mm.

In addition, the ML-C 7600 features a robust machine design and durable components, making it easy to maintain and service.

Don’t settle for inferior production solutions – rely on the powerful thermoforming capabilities of the ML-C 7600 for all your industrial needs!

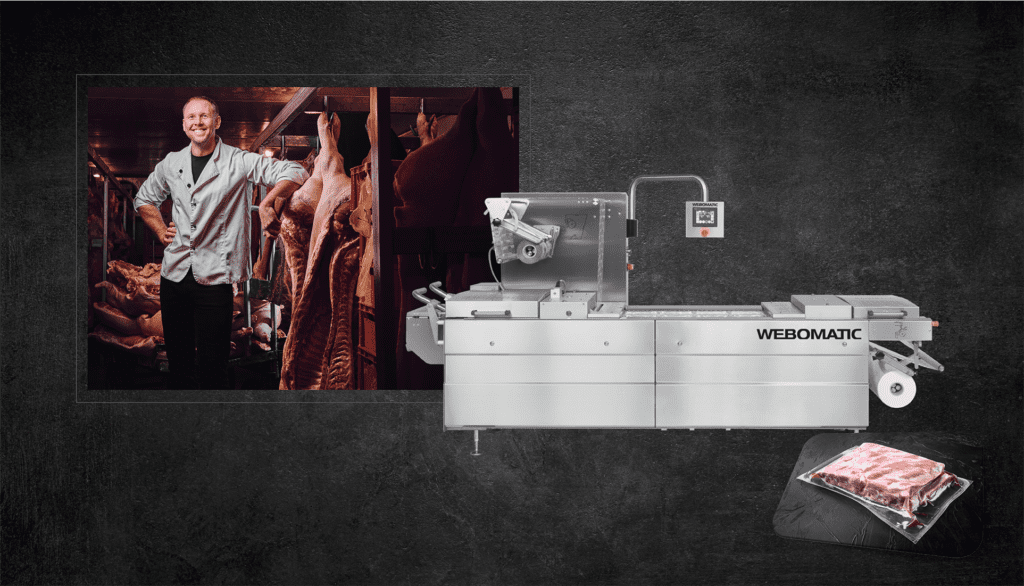

Options for packaging customization

• MAP

• Oxygen O2

• Detection system

• Skin or form shrink wrapping

• Top film formation for snap-in lids

• Gas mixer and/or analyzer

• Preheating systems

• Various cutting systems

• Opening aids, such as peel corners, bend peel, etc.

• Various pack coding and printing systems, such as:

– Labelling equipment

– Print mark control

– Stamp coding

– Hot stamping

– Thermal transfer printers

– Ink jet

– Laser systems

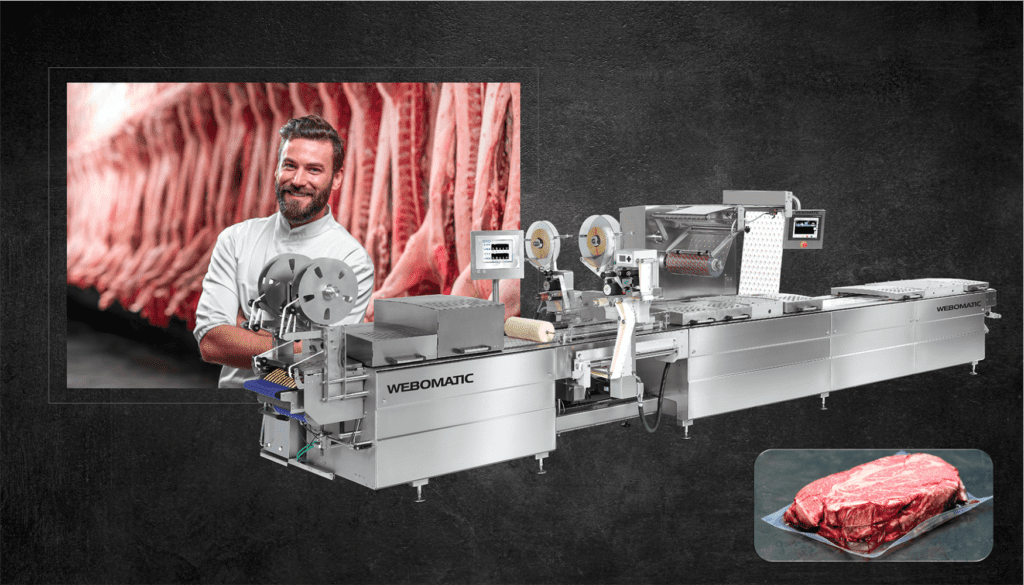

Options for packaging efficiency and process optimization

• WEBOMATIC On-The-Fly format changeover

• Quick change device for format change

• Jumbo roller device (straight or at 90° angle)

• Support rollers in the loading zone

• Film strip rewinder

• Height-adjustable split conveyor belt

• Safe water cooling system

• Stroke limitation via SPS control

• Synchronization with automatic supply system

• Various PLC control based tools:

– Communication module

– Remote diagnostics

– Advanced production data analysis

– Customization and tailoring of further

– Digitization concepts