Find the ideal

Vacuum Packaging Solution

for your Product

The optimal Vacuum Packaging of Food and Non-Food Products

WEBOMATIC offers one of the most extensive and individual delivery programs of robust and reliable vacuum packaging machines, all manufactured in Germany, of food and non-food products such as food, medical products or highly sensitive industrial articles.

Our customers are from trade, gastronomy and industry.

Table Machines

Single Chamber Machines

Small shrinking - Line

Tray Sealers

chamber belt machines

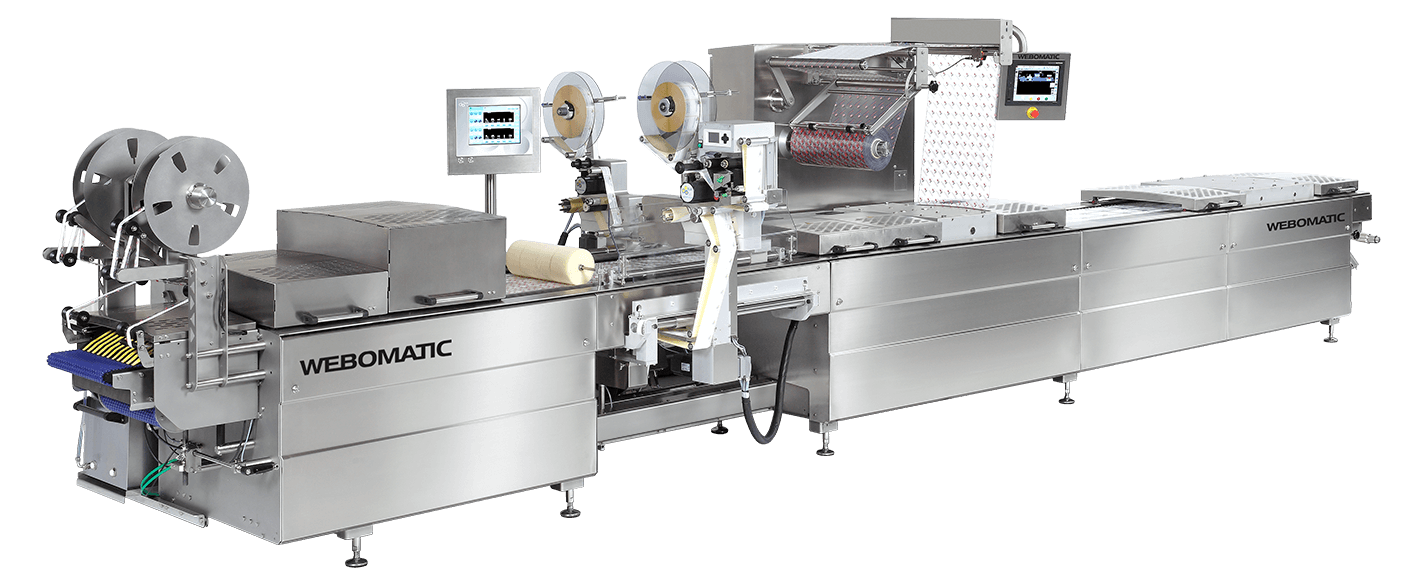

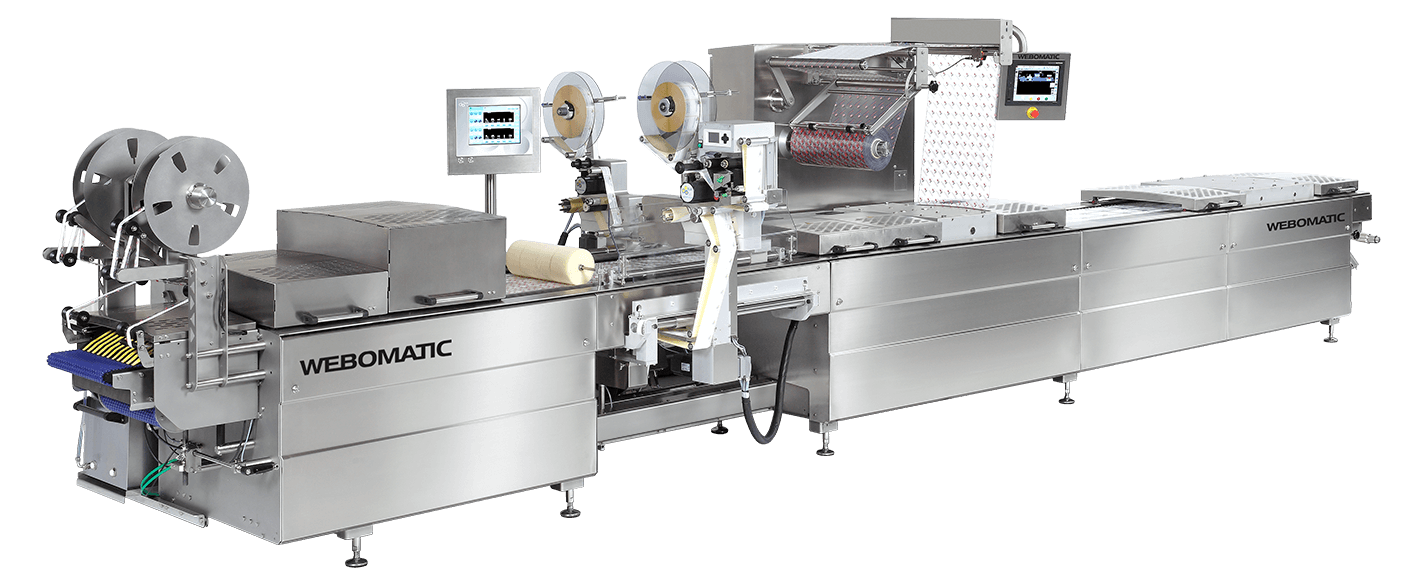

THERMOFORMING MACHINES

DISCOVER

Cheese

Discover the ideal packaging equipment for your small, medium, or large cheese production.

Good packaging means good cheese! How it looks and feels is also important. WEBOMATIC offers many options, from simple to environmentally friendly.

This not only helps the planet, but also makes customers want to buy more.

DISCOVER

MEAT: Beef, Pork, Poultry, Veal and exotic meats

The appearance of meat plays a key role in customers' purchasing decisions.

At WEBOMATIC we understand this and that's why our machines are designed to process and pack meat in a high quality, efficient and attractive way that will attract the attention of every passing customer and ultimately result in more sales.

Table Machines

Single Chamber Machines

Small shrinking - Line

Double

Chamber Machines

chamber belt machines

Large Shrinking line

Tray Sealers

THERMOFORMING MACHINES

LINE SOLUTIONS

Table Machines

Single Chamber Machines

chamber belt machines

Tray Sealers

THERMOFORMING MACHINES

LINE SOLUTIONS

DISCOVER

FISH &

SEAFOOD

Discover our optimal packaging solutions for top protection of your products.

DISCOVER

Sausage and cold cuts

Discover our packaging solutions for your business.

Table Machines

Single Chamber Machines

Small shrinking - Line

Tray Sealers

chamber belt machines

Table Machines

Single Chamber Machines

Small shrinking - Line

Tray Sealers

DISCOVER

Fruit and Vegetables

WEBOMATIC offers an innovative packaging system that guarantees a constant ideal atmosphere inside the package. This prolongs shelf life and prevents your product from drying out or spoiling. Vitamins, nutrients, colours and appearance are retained. They are also easy to stack and transport.

DISCOVER

Ready Meals

In today's fast-paced world, people are busier than ever and need meals that are quick and easy to prepare.

To meet this growing demand, companies must ensure that the meals they produce are not only of the highest quality, but are also packaged in a way that keeps them fresh, tasty and easy to deliver.

To achieve this, WEBOMATIC offers high quality packaging solutions. A wide range of options are available to meet your company's requirements.

Table Machines

Single Chamber Machines

chamber belt machines

Tray Sealers

THERMOFORMING MACHINES

Table Machines

Single Chamber Machines

THERMOFORMING MACHINES

DISCOVER

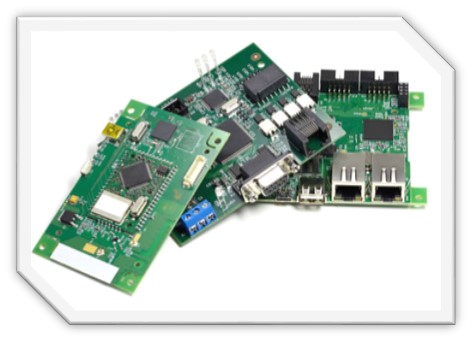

Industrial and Consumer Products

In the non-food sector, WEBOMATIC machines are used to provide protective packaging for your products. This protects them from environmental influences such as water, dust, and moisture. The protective packaging facilitates safe and efficient storage and transport of the packaged products.

DISCOVER

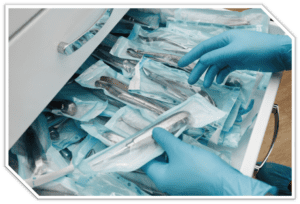

MEDICINE

Special packaging is essential for medical products to ensure they stay sterile and safe from contamination during transport and storage. WEBOMATIC provide customized packaging solutions.

Table Machines

Single Chamber Machines

chamber belt machines

Tray Sealers