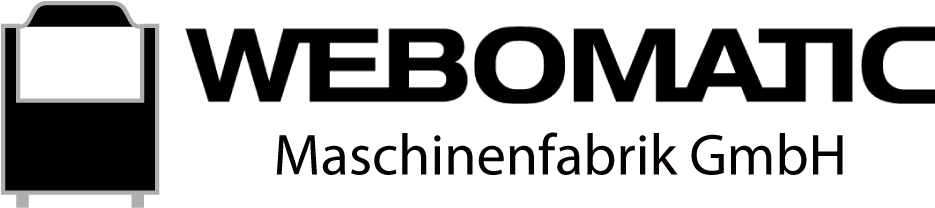

Die Tiefziehmaschine ML-C 7600 – höchste Produktionsleistung bei erstklassiger Qualität.

Die WEBOMATIC Tiefziehmaschine ML-C 7600 ist die Hochleistungslösung für die industrielle Serienfertigung anspruchsvoller Tiefziehverpackungen in bis zu drei Schichten pro Tag.

Sie vereint jahrzehntelange Erfahrung mit Geschwindigkeit, Präzision und Potenzial.

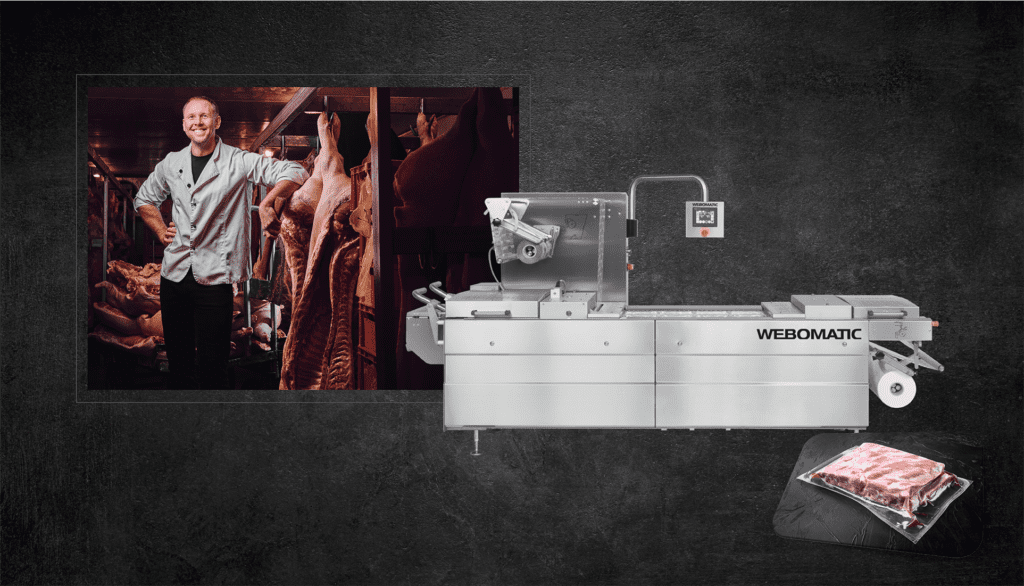

Je nach Ausstattung verarbeitet diese industriell ausgerüstete Tiefziehmaschine alle handelsüblichen Folienmaterialien mit einer Breite von bis zu 662 mm, einer Abzugslänge von bis zu 1.000 mm und einer Ziehtiefe von 190 mm.

Mit dem robusten Maschinendesign und den langlebigen Komponenten ist die ML-C 7600 wartungs- und servicefreundlich.

Optionen für Verpackungsindividualisierung

- MAP

- Sauerstoff O2

- Haut- oder Formschrumpfverpackung

- Oberfolienbildung für Snap-In-Deckel

- Gasmischer und/oder Analysegerät

- Vorheizsysteme

- Kniefreie Ladezone

- Verschiedene Formverfahren

- Verschiedene Schneidesysteme

- Verschiedene Packungscodier- und Drucksysteme, wie:

– Etikettiergeräte, unten und oben

– Druckmarkensteuerung

– Stempelcodierung

– Heißprägung

– Thermotransferdrucker

– Tintenstrahl

– Lasersysteme

- Öffnungshilfen, wie Peel-Ecken, Knick-Peel, etc.

- Detektionssysteme

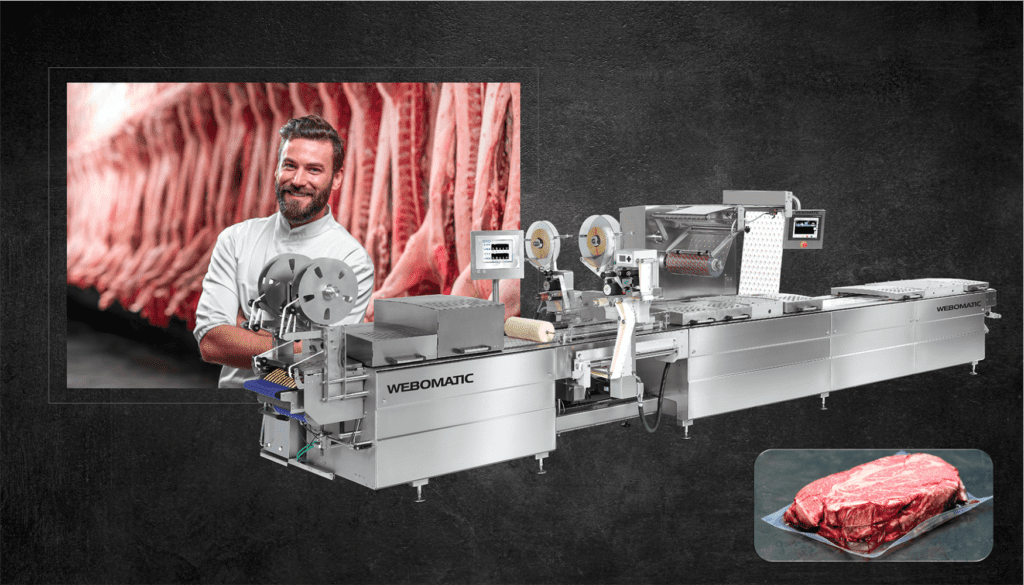

Optionen für Verpackungseffizienz und Prozessoptimierung

- Verschiedene SPS-Steuerungen basierte Hilfsmittel:-Kommunikationsmodul

– Ferndiagnose

– erweiterte Produktionsdatenanalyse

– Anpassung und Maßschneiderung von weiteren

– Digitalisierungskonzepte

- WEBOMATIC On-The-Fly Formatwechsel

- Schnellwechselvorrichtung für Formatwechsel

- Jumbo-Rollenvorrichtung (gerade oder im 90°-Winkel)

- Unterstützungsrollen in der Ladezone

- Filmstreifenaufwicklung

- Höhenverstellbares geteiltes Förderband

- Sicheres Wasser-Kühlsystem

- Hubbegrenzung über SPS-Steuerung

- Synchronisation mit automatischem Versorgungssystem