WEBOMATIC®

Thermoforming Machines

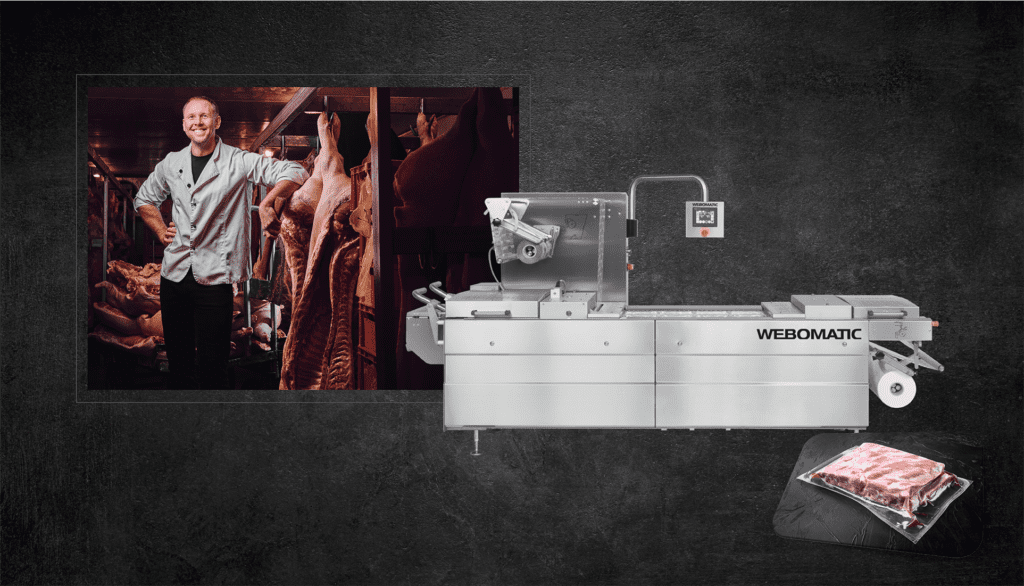

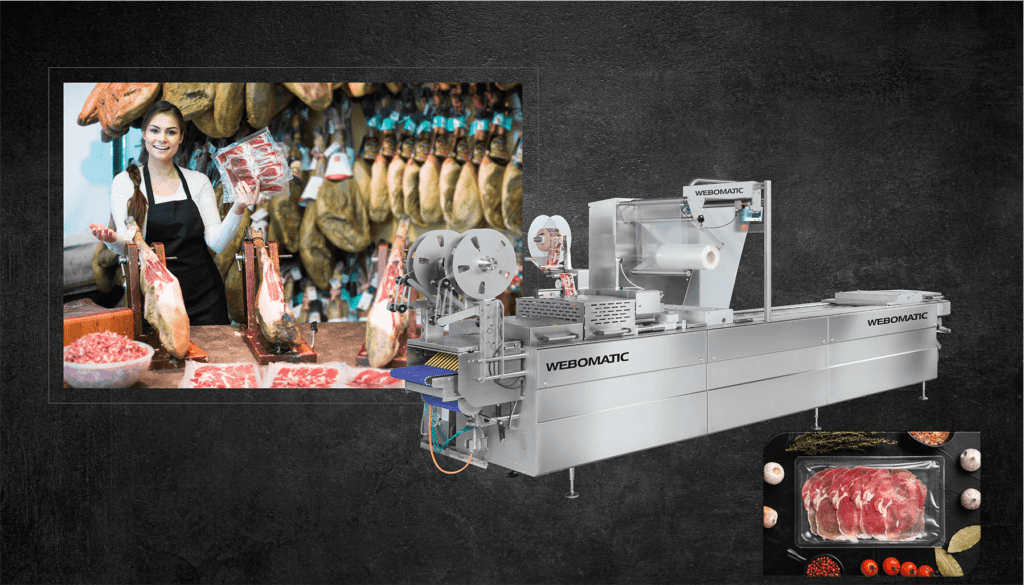

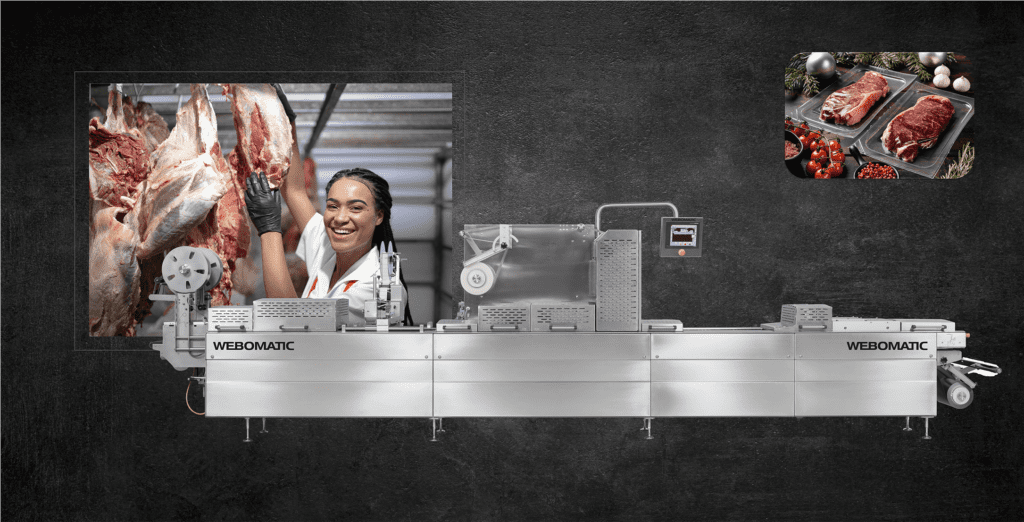

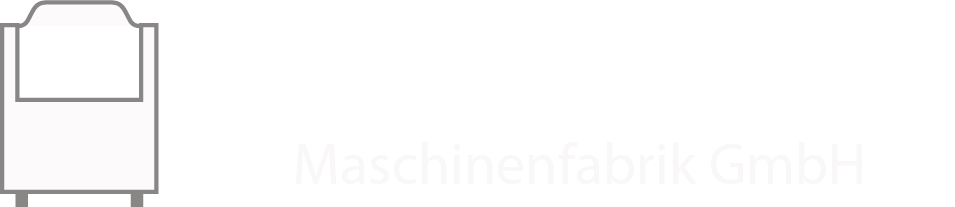

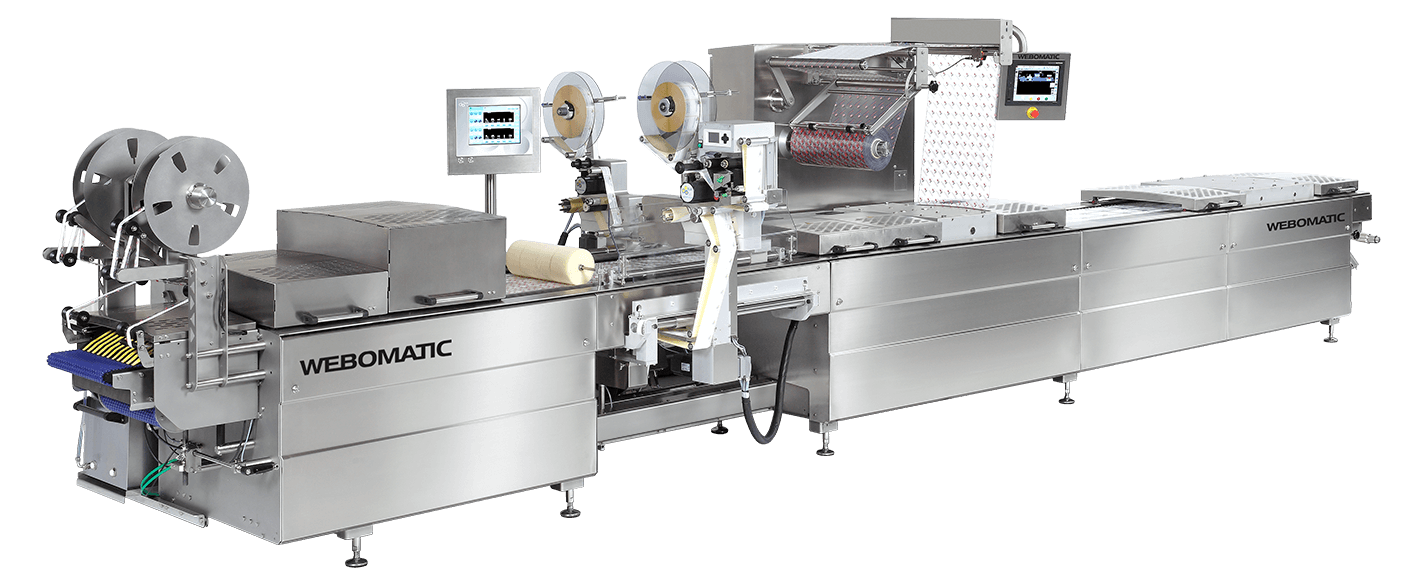

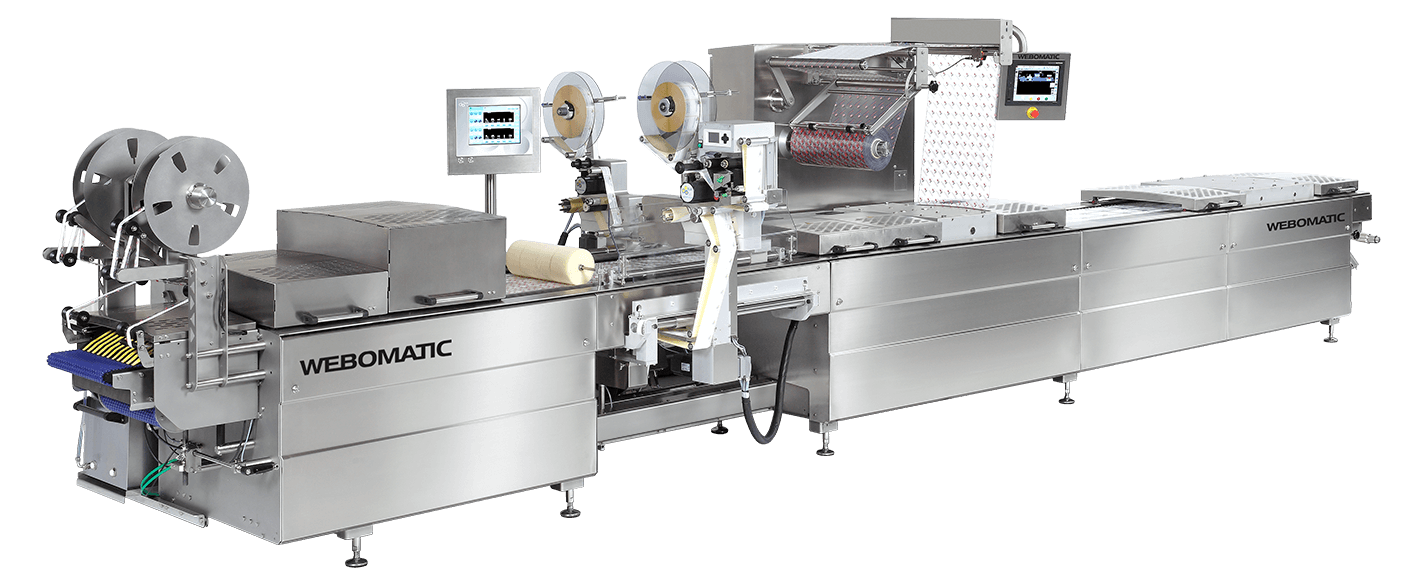

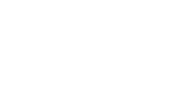

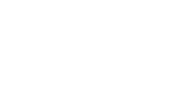

WEBOMATIC® ML-C 5600

This thermoforming packaging machine impresses with high output, quality, and ease of maintenance and service.

WEBOMATIC® ML-C 5600

This thermoforming packaging machine, which was designed to meet the highest demands for industrial-sized production, impresses with its high performance, quality, and ease of maintenance and service.

WEBOMATIC®

ML-C 5600

Thermoforming Machines

- Industrial capacity processing

- Modular design with expandable length up to 20 m

- Processing of flexible and rigid films, also suitable for special films and top film forming.

- Processes film width up to 562 mm,

repeat length up to 600 mm.

-Optimal distribution of power and grip by

double knee lever system

- High degree of customization.

Play Now

WEBOMATIC®ML-C 5600

Thermoforming Machines

- Industrial capacity processing.

- Modular design with expandable length up to 20 m.

- Processing of flexible and rigid films, also suitable for special films and top film forming.

- Processes film width up to 562 mm,

repeat length up to 600 mm.

-Optimal distribution of power and grip by

double knee lever system.

- High degree of customization.

Play Now

Thermoforming Machines ML-C 5600

The ML-C 5600 meets the highest demands for industrial

sized production

The innovative Thermoforming machine, equipped with highly dynamic servo motors, was built with special emphasis on the prevention of dirt traps.

With its film width, repeat

length/index and optimized lifting movement, the

machine is ideal for automated operation in a

packaging line with integrated slicers, pick-andplace robots, multi-head weighers etc. .

Depending on the specification, it can

produce rigid films up to 600 µm with an

width of up to 562 mm and index lengths up to

600 mm.

Thermoforming Machines ML-C 5600

The ML-C 5600 is suited for high-speed operation.

The innovative Thermoforming machine, equipped with highly dynamic servo motors, was built with special emphasis on the prevention of dirt traps.

With its film width, repeat

length/index, and optimized lifting movement, the

machine is ideal for automated operation in a

packaging line with integrated slicers, pick-and-place robots, multi-head weighers, etc.

Depending on the specification, it can

produce rigid films up to 600 µm with a

width of up to 562 mm and index lengths up to

600 mm.

WEBOMATIC ML-C 5600

Zur Erstellung maßgeschneiderter, anspruchsvoller Tiefziehverpackungen auch in großer Stückzahl ist für diese Maschine eine Fülle von Sonderausstattungen vorbereitet. Dazu gehören zum Beispiel eine verlängerte Einlegestrecke, auch kniefrei, und ein verlängerter Auslauf.

Wichtig auch die Schnitttechnik: Neben

den üblichen Schnitttechniken für Weich und Hartfolien beherrscht die ML-C 5600 optional auch zum Beispiel den Zickzack und Perforationsschnitt.

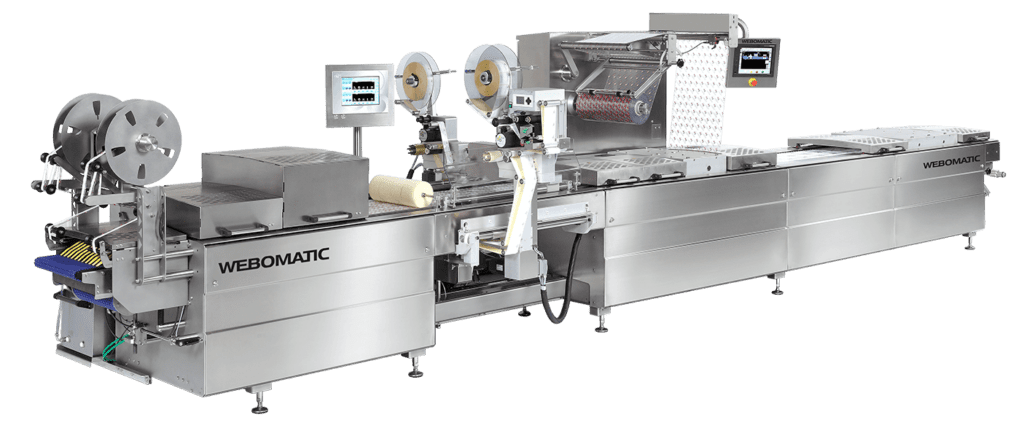

WEBOMATIC® thermoforming machines extend the shelf life of your food.

In this way, they reach the end consumer's table with their freshness, color and taste intact.

Packaging Examples

Have we awakened your interest?

WEBOMATIC ML-C 5600

A wealth of special equipment is prepared for this machine for the production of tailor-made, sophisticated thermoformed packaging, even in large quantities.

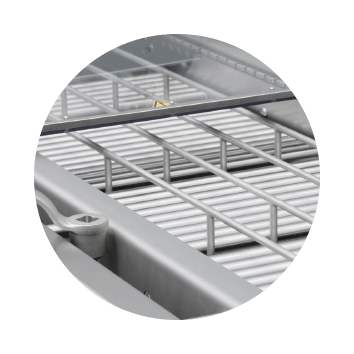

The innovative lifting system with compact hygienic cylinders and a double-knee lever, for example, guarantees a high closing pressure of the die-cut format for precise movements and formidable pack designs.

Cutting technology is also important: In addition to the usual cutting techniques for flexible and rigid films, the ML-C 5600 can optionally master zigzag and perforation cuts.

65 years of experience in the development of automated and integrated packaging solutions, tailored to customer needs

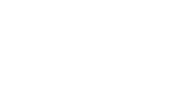

Traysealer Packaging Lines

WEBOMATIC ML-C 5600

A wealth of special equipment is prepared for this machine for the production of tailor-made, sophisticated thermoformed packaging, even in large quantities.

The innovative lifting system with compact hygienic cylinders and a double-knee lever, for example, guarantees a high closing pressure of the die-cut format for precise movements.

Cutting technology is also important: In addition to the usual cutting techniques for flexible and rigid films, the ML-C 5600 can optionally master zigzag and perforation cuts.

Its modular construction allows flexible expansions to a complete packaging line, and it provides a variety of options for individual packages.

Vacuum packaging extends the shelf life of food products.

In this way, they reach the table of the end consumer with intact freshness, colour and taste.

Distinctive packaging designs

Packaging examples

Depending on the request, our machines can produce: Vacuum, MAP, Shrink or Skin Packaging, which can be specially adapted to the product through various variation options.

Use the diverse options available

to customize your machines for production

The height-adjustable roller chain in the infeed zone supports a consistently transport of heaviest

products in the loading area.

Saving time by changing the format “on

the fly” during the running production by

switching on the PLC control with

On-The-Fly Format Change.

With top film forming, stable Snap-In Lids are created out of rigid top film to fit resalable

packages.

ML-C 5600

The WEBOMATIC® ML-C 5600 is a thermoforming packaging machine, designed to meet the highest demands for industrial-sized production. It impresses with its high performance, quality, and ease of maintenance and service.

With a length of 3.7 m in the basic configuration, it fits any location. However, it can be extended to up to 20 m, for example, for a generous insertion area.

Its modular design and construction allow flexible expansion to a complete packaging line, and it provides a variety of options for customized packaging – be it the embossing of company logos, different cutting techniques, or skin packs.

Thanks to the intelligent control system, which also allows remote maintenance, complementary systems are synchronized with the machine.

The machine’s innovative lifting system includes compact hygienic cylinders and a double knee lever, ensuring high closing pressure of the format die for precise movements and extraordinary packaging designs.

In order to reduce compressed air consumption, is the combination of individual stroke adjustment and lifting simple but efficient. Also, vacuum valves are placed directly at the die. This means even shorter ways to create a vacuum, and that adds up to a quicker production.

The ML-C 5600 can process, depending on specifications and equipment, soft and rigid films (PA/PE, PET, PVC, PP, PS) with a width of up to 562 mm in repeat lengths of up to 600 mm.

The highly dynamic servo drive ensures precise film transport.

The WEBOMATIC® ML-C 5600 is characterized by high speed and precision.

| Technical Specifications | |

| ML-C 5600 | |

| Area of Use | Food, Non-Food |

| Machine dimensions: | Length: 5.260 – 19.500 mm Width: 1.030 – 1.270 mm (depending on film width) Height: 1.980 mm (± 35 mm) |

| Size / Capacity | ●●●● |

| Output | ●●●● |

| Degree of customization | ●●●● |

| Packaging shape variants | freely definable |

| Packaging style | Vacuum, MAP, Pseudo-skin, |

| Protrude-skin, Form shrink, 2pack | |

| Repeat length/Index: | 200 – 600 mm |

| (max. 400 mm with pre-heating) (only skin: 200 – 400 mm) | |

| Draw depth | Max.130 mm / max. 70 mm – skin |

| Bottom film width | 322 – 562 mm |

| Bottom film: Flexible film | PA/PE, Tyvec, max. 1200 μm |

| Bottom film: Rigid film | e.g. PET, PVC, PP, PS |

| Top film: Flexible film | e.g. PA/PE, Tyvec, PP |

| Top film: Rigid film | Optional |

| WEBOMATIC CleanDesign® | ● |

| WEBOMATIC Sealing Technology | ● |

| Forming procedures | Standard: compressed air |

| Optional: compressed air and vacuum, | |

| plug assist forming | |

| Top film forming | Optional |

| Cutting | Standard: guillotine cut |

| Optional: Zigzag cut, Perforation cut, Round corners, Squeezing knife, Strip punch, Contour or complete cut | |

| Film rewinding with dancer arms | Optional |

| Peel Corners | Optional |

| Pre-heating | Optional |

| WEBOMATIC On-The-Fly Format Change | Optional |

| Pseudo-skin | Optional |

| Protrude-skin | Optional |

| WEBOMATIC 2pack | Optional |

| Form shrink | Optional |

Options for Packaging Customization

| ML-C 5600 | |

| • MAP | O |

| • Oxygen O2 | O |

| • Print mark control | O |

| • Pseudo-Skin | O |

| • Protrusion-Skin | O |

| • Form shrink | O |

| • Top film forming for snap-in lids | O |

| • Various cutting systems | O |

| • Opening aids, such as peel corners, bend peel, etc. | O |

| • Various pack coding and printing systems, such as: | |

| – Labelling equipment | O |

| – Print mark control | O |

| – Stamp coding | O |

| – Thermal transfer printers | O |

| – Ink jet | O |

| – Laser systems | O |

Other options are available, CONTACT US!

We will gladly advise you

Options for Packaging Efficiency and Process Optimization

| ML-C 5600 | |

| • Support rollers in the loading zone | O |

| • Film strip rewinder | O |

| • Height-adjustable split conveyor belt | O |

| • Safe water cooling system | O |

| • Stroke limitation via PLC-control | O |

| • Synchronization with automatic supply system | O |

| • Gas mixer and/or analyzer | O |

| • Preheating systems | O |

| • Various PLC control based tools: | |

| – Remote diagnostics | O |

| – Advanced production data analysis | O |

| – Customization and tailoring of further | O |

| – Digitization concepts | O |

More options are available , Get in Touch!