Packaging solutions

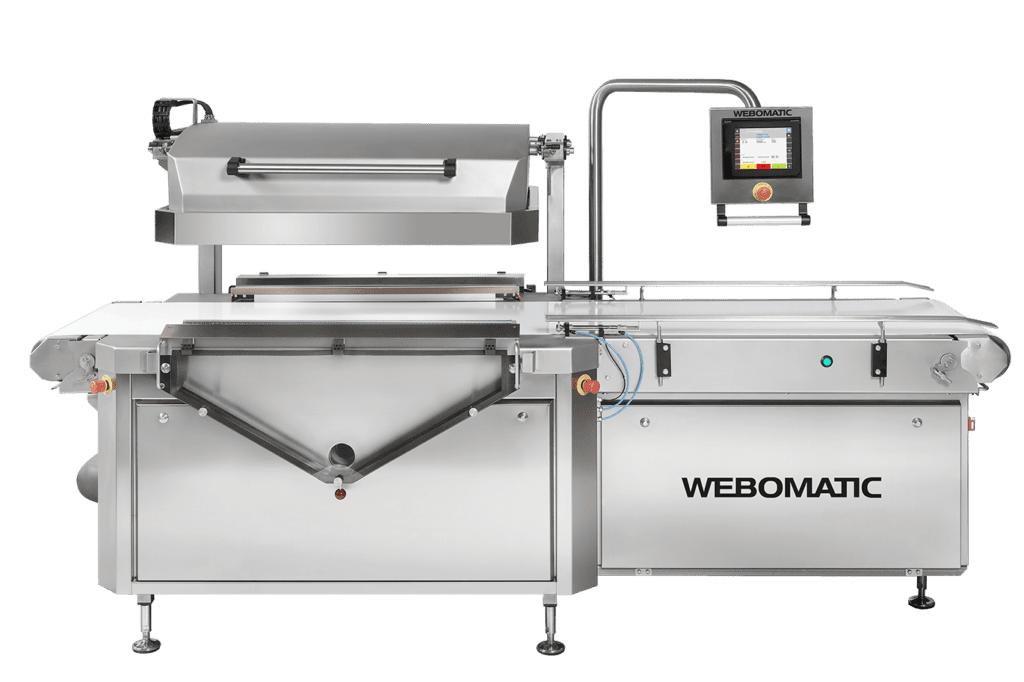

The WEBOMATIC CL-C 950 offers the best ease of use, reliable efficiency, and highly versatile.

Products of the most varied sizes can be flexibly packed in one process.

WEBOMATIC Maschinenfabrik GmbH

Wir bauen Vertrauen seit 1958

Ideal for medium to large production capacities is the CL-C 950 in many application areas,

the best solution for fully automatic and economical packaging in pouches.

Packaging solutions

The WEBOMATIC CL-C 950 offers the best ease of use, reliable efficiency, and highly versatile.

Products of the most varied sizes can be flexibly packed in one process.

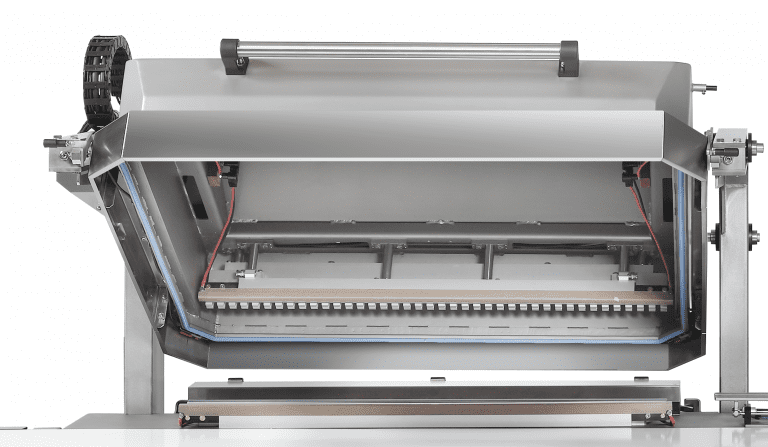

The WEBOMATIC CleanDesign® roll-on lid is an innovative and patented feature that allows fast, thorough, and effortless cleaning of the inside of the lid as well.

The lid design allows liquids to drain off without spilling onto the conveyor belt.

This feature minimizes the risk of contamination, provides effective protection for your product, and reduces downtime for machine cleaning.

Discover the following options that allow you to customize the machine to meet the requirements of your products.

The CL-C 950 vacuum packaging machine offers excellent ease of use and safe efficiency, as it can package products of varying sizes in a single operation. In addition to a cost-effective base model, various options and equipment configurations are available to cater to individual needs.

Thanks to the well-conceived design of the CL-C 950 in WEBOMATIC CleanDesign®, maintenance and cleaning can be carried out in a matter of minutes. The innovative Roll-Back-Lid in WEBOMATIC CleanDesign® facilitates easy, fast, and thorough hygiene cleaning of the lid’s inside.

Liquids can flow out of the back of the machine without getting on the transport belt.

The optional split shuttle conveyor belt simplifies the packaging process, requiring only one operator to manually load the chamber belt machine, with individual belt speeds that can be continuously regulated.

Optional remote diagnostic systems for production and service with data acquisition, maintenance modules, as well as user identification pins, provide greater transparency.

The CL-C 950 can be combined with the following components to form an automatic shrink line:

• CL-C 950 (Chamber Belt Machine)

• CB 60-100 (Conveyor Belt)

• STCW 60-L (Automatic Shrink Unit)

• DU 60-L (Automatic Dryer Unit)

• PD 60-150 (Exit roller)

• LS 150 (Rotary Table)

Several other configurations can be arranged as per space and operational requirements.

| Technical Data: | |

| Design specifications: | Stainless Steel AISI 304 |

| Machine dimensions: | 2.870 x 1.185 x 1.750 mm (W x D x H) |

| Chamber dimensions: | 1.050 x 850 x 290 mm (W x D x H) |

| Net Weight: | approx. 1.150 kg, without vacuum pump |

| Sealing: | Double seam sealing, 2x 4 mm from top |

| Seal bar length: | 950 mm each side |

| Max. product length: | 640 mm |

| Max. product height: | 250 mm |

| PLC control | Mitsubishi touch screen, 8,4″ |

| Cycle capacity: | up to 3 cycles/min., depending on vacuum, pump and product |

| Vacuum Pump: | 600 m3/h, 1000 m3/h (other sizes, external, on request)) |

| ROLL BACK- Lid: | Roll Back-Lid in WEBOMATIC CleanDesign® |

| for easy and thorough machine lid cleansing |

| • Vacuum-Sensor Control |

| • Mitsubishi PLC control unit; up to 100 programms |

| • Mitsubishi touch screen, 8,4″ |

| • Diagnosis system for production and service |

| • Control and permanent indication of the operating status |

| • Conveyor belt speed, continuously adjustable |

| • Stainless steel drum motor |

| Bi-Active Sealing |

| Soft-Air |

| Bag Perforation |

| Trim removal |

| Special conveyor |

| Communication Module |

| External contact |

| Electric cabinet heating: |

| Special voltage |

Don’t miss our future updates! Subscribe today!

Office:

Mo-Thu 7:30 – 16:15

Fr 7:30 – 15:00

(UTC+1)

Service:

Mo-Thu 7:00 – 15:30

Fr 7:00 – 14:00

©2023 WEBOMATIC All Rights Reserved.